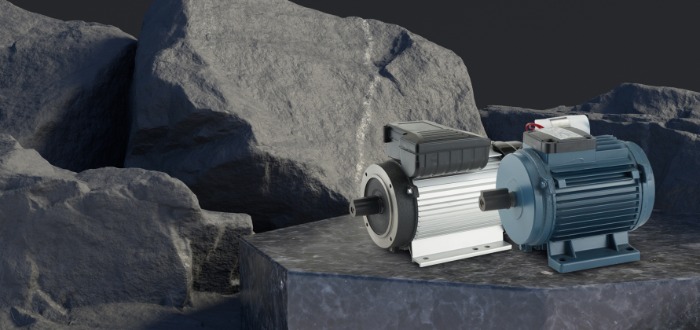

Maintenance plays a crucial role in ensuring the reliability and longevity of motors used in air compression systems. Among these, the Air Compressor Motor, commonly built as a 3 phase asynchronous induction motor, requires regular attention to maintain its operational efficiency and prevent unexpected failures. Implementing effective maintenance practices can significantly extend the service life of these motors and reduce downtime in industrial operations.

The 3 phase asynchronous induction motor is widely valued for its simple and durable construction, which allows it to perform reliably under continuous load conditions. However, without proper maintenance, the motor’s components may experience wear and degradation, which can cause efficiency losses or mechanical failures. For Air Compressor Motors, which often operate in demanding environments, maintenance is especially important to sustain performance.

Routine inspection is a fundamental maintenance practice. Visual checks for signs of overheating, corrosion, or physical damage help identify potential issues early. For the 3 phase asynchronous induction motor, monitoring the condition of windings and insulation is vital, as insulation breakdown can cause short circuits or motor failure.

Lubrication of bearings is another essential maintenance task. Bearings support the rotor and enable smooth rotation, so their proper lubrication reduces friction and wear. In Air Compressor Motors, which often run for extended periods, maintaining the right lubrication schedule helps prevent bearing failure, which can cause significant motor damage and operational interruptions.

Cleaning is also critical to prevent dust and debris accumulation. Dust can obstruct ventilation openings and reduce the cooling efficiency of the motor, causing excessive heat buildup. Overheating may degrade the insulation and shorten the lifespan of the 3 phase asynchronous induction motor. For Air Compressor Motors, particularly those in dusty industrial settings, regular cleaning of the exterior and ventilation systems supports reliable operation.

Electrical connections should be checked periodically to ensure they remain tight and free from corrosion. Loose or corroded connections can cause voltage drops or arcing, which negatively impact the motor’s performance and safety. Maintaining proper electrical connections helps the Air Compressor Motor operate within its designed parameters.

Monitoring motor temperature during operation provides valuable information about its health. Excessive temperature rises can indicate overloading, inadequate ventilation, or internal faults. Using temperature sensors or infrared thermometers, maintenance teams can identify abnormal conditions early and take corrective actions to protect the 3 phase asynchronous induction motor.

Vibration analysis is another useful maintenance technique. Excessive vibration may result from imbalance, misalignment, or bearing defects. Detecting these issues promptly can prevent further damage and maintain smooth motor operation. For Air Compressor Motors, controlling vibration contributes to mechanical stability and energy efficiency.

In addition to scheduled maintenance, keeping detailed records of inspections, repairs, and operating conditions helps track the motor’s performance over time. This information supports predictive maintenance strategies, allowing operators to plan interventions before failures occur and less unplanned downtime.

Proper motor storage and handling during installation or repairs also affect lifespan. The 3 phase asynchronous induction motor should be stored in clean, dry environments and protected from physical damage. Careful handling prevents damage to sensitive components, which is particularly important for Air Compressor Motors destined for demanding industrial applications.

For industrial users, investing in a comprehensive maintenance program for Air Compressor Motors ensures that the 3 phase asynchronous induction motor continues to meet operational demands while less repair costs and downtime. Proper care of these motors ultimately contributes to smoother production processes and better return on investment.