The industrial sector is constantly evolving, with new technologies driving efficiency, sustainability, and performance. Among these innovations, Permanent Magnet Motors have emerged as a game-changer, offering significant advantages over traditional motor designs. Their impact spans multiple industries, including manufacturing, automation, and cleaning systems, where Cleaning Machine Motors play a crucial role.

The advanced Efficiency of Permanent Magnet Motors

One of the key reasons Permanent Magnet Motors are gaining traction is their exceptional energy efficiency. Unlike conventional induction motors, which rely on electromagnetic induction to generate torque, Permanent Magnet Motors use high-strength magnets to create a constant magnetic field. This design reduces energy loss, pilots to lower power consumption, and improves operational efficiency.

For industries that rely on heavy-duty equipment, such as those using Cleaning Machine Motors, this efficiency translates into cost savings and reduced environmental impact. Since Permanent Magnet Motors maintain consistent performance even under variable loads, they are ideal for applications requiring precision and reliability.

Enhanced Performance in Cleaning Machine Motors

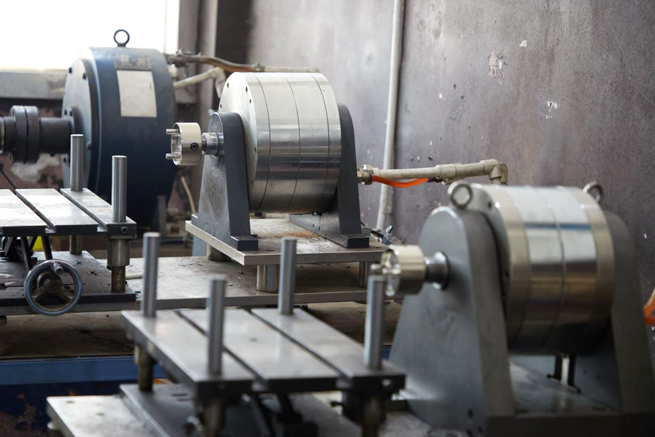

Cleaning Machine Motors are essential in commercial and industrial cleaning systems, where durability and efficiency are critical. Traditional motors often struggle with heat generation and wear over time, but Permanent Magnet Motors address these challenges effectively.

Thanks to their compact design and reduced friction, Permanent Magnet Motors deliver higher torque at lower speeds, making them well-suited for Cleaning Machine Motors used in scrubbers, sweepers, and pressure washers. Their ability to operate smoothly under varying conditions ensures longer service life and fewer maintenance requirements—a major advantage for industries dependent on high-performance cleaning solutions.

Sustainability and Environmental Benefits

As industries worldwide shift toward greener practices, Permanent Magnet Motors offer a sustainable alternative to conventional motor technologies. Their energy-efficient operation reduces electricity consumption, lowering carbon footprints in industrial settings.

In applications such as Cleaning Machine Motors, where continuous operation is common, the reduced energy waste of Permanent Magnet Motors contributes to significant long-term savings. Additionally, because these motors generate less heat, they minimize the risk of overheating, further enhancing their reliability in demanding environments.

Durability and Reduced Maintenance Needs

Another compelling advantage of Permanent Magnet Motors is their robust construction. With fewer moving parts compared to traditional motors, they experience less mechanical wear, resulting in extended operational lifespans.

For Cleaning Machine Motors, this durability is particularly valuable. Industrial cleaning equipment often operates in harsh conditions, including exposure to dust, moisture, and chemicals. Permanent Magnet Motors are designed to withstand such challenges, reducing downtime and maintenance costs. Their ability to maintain consistent performance over time makes them a dependable choice for businesses seeking long-term reliability.

Future Trends and Industrial Adoption

The growing adoption of Permanent Magnet Motors across industries highlights their transformative potential. As technology advances, we can expect even greater improvements in efficiency, power density, and smart control integration.

In the realm of Cleaning Machine Motors, innovations such as brushless designs and IoT-enabled monitoring are further enhancing performance. These developments align with the broader industrial trend toward automation and energy conservation, reinforcing the role of Permanent Magnet Motors as a cornerstone of modern engineering.

By integrating Permanent Magnet Motors into industrial systems, companies can achieve greater productivity, lower costs, and a reduced environmental footprint, making them a smart investment for the future.