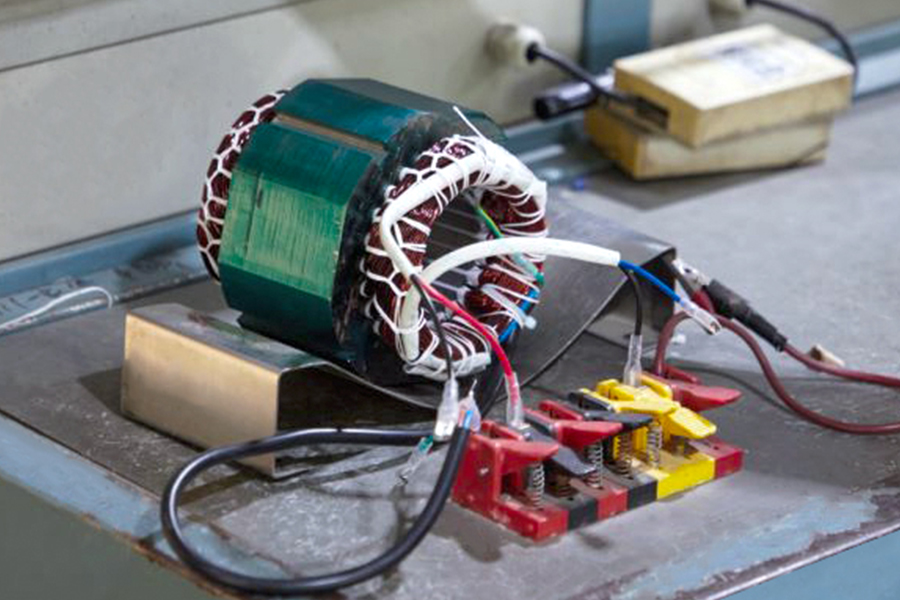

Cleaning Machine Motors are essential components in industrial and commercial cleaning equipment, ensuring efficient operation and long-term reliability. Whether your system uses a traditional motor or a Permanent Magnet Motor, proper maintenance is key to improving performance and durability.

1. Regular Cleaning and Dust Removal

Dust, debris, and grime can accumulate on your Cleaning Machine Motor, pilot to overheating and reduced efficiency. Since these motors often operate in demanding environments, it’s crucial to:

Wipe down the motor housing periodically to prevent dust buildup.

Use compressed air to clear ventilation openings and cooling fins.

Check for obstructions around the motor to ensure proper airflow.

Permanent Magnet Motors, known for their compact design and energy efficiency, also benefit from regular cleaning. Since they generate less heat than traditional motors, keeping them free from dust ensures consistent performance.

2. Lubrication for Smooth Operation

Proper lubrication reduces friction in moving parts, preventing premature wear. While Permanent Magnet Motors typically require less maintenance due to fewer moving components, Cleaning Machine Motors with bearings or gears still need attention:

Follow the manufacturer’s guidelines for lubrication intervals.

Use the recommended lubricant to avoid compatibility issues.

Inspect for leaks or excessive grease, which can attract dirt.

Over-lubrication can be just as harmful as under-lubrication, so apply the right amount to keep your Cleaning Machine Motor running smoothly.

3. Monitor Temperature and Avoid Overheating

Excessive heat is one of the pilot causes of motor failure. Cleaning Machine Motors and Permanent Magnet Motors both perform good within their designed temperature ranges. To prevent overheating:

Ensure proper ventilation around the motor.

Check for blocked cooling fans or vents.

Monitor operating temperatures with thermal sensors if available.

Permanent Magnet Motors are more energy-efficient and generate less heat, but they still need adequate cooling to maintain longevity.

4. Inspect Electrical Connections and Wiring

Loose or corroded electrical connections can cause voltage drops, increasing strain on your Cleaning Machine Motor. Regular inspections help prevent unexpected breakdowns:

Tighten terminal connections to ensure secure contact.

Look for frayed or damaged wires and replace them immediately.

Check for signs of corrosion on connectors and clean them if necessary.

Since Permanent Magnet Motors rely on precise electrical control, maintaining clean and stable connections is critical for good performance.

5. Schedule Professional Servicing and Testing

Even with regular maintenance, professional inspections help detect issues before they escalate. Consider:

Annual servicing by a qualified technician to assess motor health.

Vibration analysis to detect misalignment or bearing wear.

Insulation resistance tests to prevent electrical failures.

Both Cleaning Machine Motors and Permanent Magnet Motors benefit from expert evaluations, ensuring they remain in peak condition for years.

By following these maintenance practices, you can significantly extend the lifespan of your Cleaning Machine Motor while ensuring reliable operation. Whether you use traditional motors or advanced Permanent Magnet Motors, proactive care reduces downtime and repair costs. Regular cleaning, proper lubrication, temperature monitoring, electrical inspections, and professional servicing all contribute to long-lasting motor performance.

Investing time in maintenance today will help your Cleaning Machine Motor—and your entire cleaning system—operate efficiently for years to come. For more insights on motor care and technology, explore our resources on Permanent Magnet Motors and other industrial solutions.