In recent years, there has been a growing focus on improving the energy efficiency of industrial equipment, particularly in electric motors. Among these, the 3 phase asynchronous induction motor plays a crucial role due to its widespread use in various manufacturing and commercial applications. One specific area of interest is the Air Compressor Motor, a vital component in air compression systems used across multiple industries. Enhancing the energy efficiency of these motors not only reduces operational costs but also contributes to lowering environmental impact.

The 3 phase asynchronous induction motor is widely recognized for its durability, relatively simple design, and reliable performance. However, its energy consumption can vary significantly depending on design improvements and manufacturing standards. In the context of Air Compressor Motors, even slight enhancements in motor efficiency can cause substantial energy savings given the continuous operation these motors often experience.

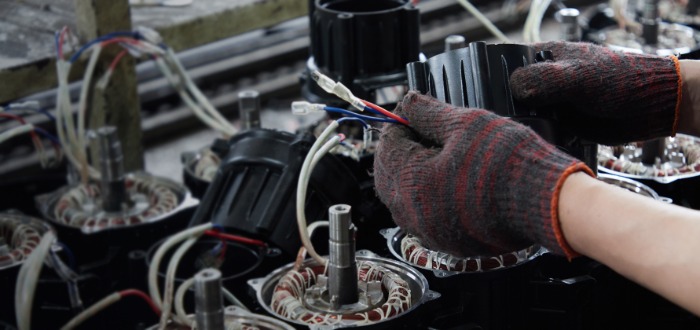

Recent technological advancements have focused on refining the motor's internal components and improving manufacturing precision. For example, improvements in the quality of the stator windings and rotor bars can reduce electrical losses, which directly impact the overall efficiency of the 3 phase asynchronous induction motor.

Another important factor in energy efficiency improvements is the optimization of motor control systems. Modern Air Compressor Motors often integrate with variable frequency drives (VFDs) to adjust the motor’s speed and torque according to real-time demand. This approach prevents unnecessary power consumption and improves the overall operational efficiency of the motor. The 3 phase asynchronous induction motor’s compatibility with such control technologies is a key advantage in its continued application.

Manufacturers have also put emphasis on reducing mechanical losses by enhancing the design of bearings and rotor dynamics. A well-balanced rotor and high-quality bearings reduce friction and mechanical wear, which not only extends the motor’s lifespan but also improves its energy efficiency. This is especially important for Air Compressor Motors, where sustained operation can put considerable mechanical stress on the motor components.

Energy efficiency improvements in the 3 phase asynchronous induction motor also contribute to meeting regulatory requirements and industry standards. Many regions have implemented stricter energy consumption regulations that encourage or require the use of energy-efficient motors in industrial equipment. This has driven manufacturers to focus on innovation and quality control during the production of Air Compressor Motors and similar motor types.

In addition to technical advancements, the maintenance of the motor plays a significant role in sustaining energy efficiency. Proper upkeep, including regular cleaning, lubrication, and timely replacement of worn parts, ensures that the 3 phase asynchronous induction motor operates within its intended performance parameters. For Air Compressor Motors, maintenance is particularly critical given the demanding environments in which they often function.

The benefits of energy-efficient 3 phase asynchronous induction motors extend beyond cost savings and regulatory compliance. By reducing energy consumption, these motors help lower greenhouse gas emissions associated with electricity generation.

The advancements in the design, manufacturing, and control of the 3 phase asynchronous induction motor have led to notable improvements in energy efficiency, especially for applications such as the Air Compressor Motor. These developments support both economic and environmental objectives, making energy efficiency a central focus in the ongoing evolution of electric motor technology.

If you are considering equipment upgrades or new installations involving Air Compressor Motors, it is advisable to explore models that incorporate recent efficiency enhancements. Doing so can contribute to reduced operational costs and support sustainability initiatives over the long term.