The performance of Air Compressor Motors is critical in a wide range of industrial applications, where reliability and efficiency are essential for continuous operation. Among the various types of motors used, the 3 phase asynchronous induction motor remains a popular choice due to its robustness and adaptability. Understanding the key factors that influence the performance of these motors helps ensure good operation and longevity in demanding industrial environments.

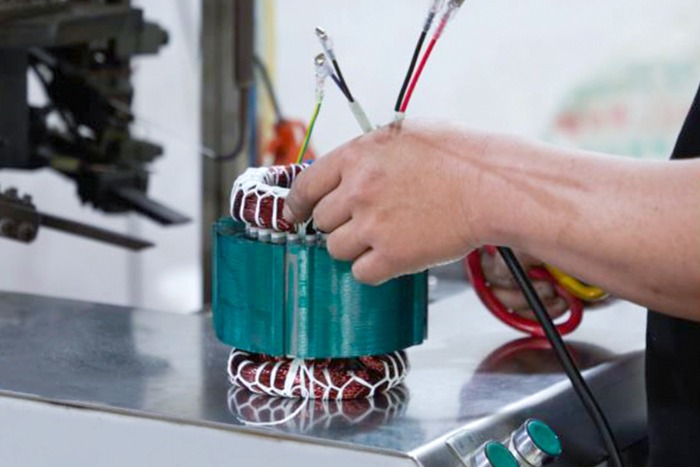

One primary factor affecting the performance of the 3 phase asynchronous induction motor used as an Air Compressor Motor is the quality of its construction. High standards in manufacturing processes, including precision winding and quality materials, can reduce electrical losses and mechanical wear. These aspects directly influence the motor’s efficiency and reliability during extended operation.

The operating environment also plays a significant role in motor performance. Air Compressor Motors often work in conditions that involve heat, dust, and vibration. Proper design considerations, such as adequate ventilation and protective housings, help maintain the 3 phase asynchronous induction motor’s performance by preventing overheating and contamination.

Load characteristics represent another important factor. The Air Compressor Motor must handle varying load demands, depending on the air compression cycle and application requirements. The 3 phase asynchronous induction motor is designed to manage these variations effectively, but operating the motor consistently within its rated load range helps avoid stress and potential damage. Oversizing or undersizing the motor can negatively affect performance and energy consumption.

Electrical supply quality, including voltage stability and frequency consistency, significantly impacts the Air Compressor Motor’s operation. Fluctuations in supply can cause inefficient performance or overheating in the 3 phase asynchronous induction motor. Using proper electrical protections and ensuring stable power input can prevent these issues and contribute to smoother operation.

Maintenance practices also influence the motor’s ongoing performance. Regular inspection of components such as bearings, windings, and cooling systems can identify wear or faults early. For Air Compressor Motors, scheduled preventive maintenance ensures the 3 phase asynchronous induction motor continues to operate at expected efficiency levels, reducing downtime and repair costs.

Another aspect to consider is the integration of control systems. Modern Air Compressor Motors equipped with variable frequency drives (VFDs) can adjust speed and torque according to system demand, optimizing performance and reducing energy consumption. The 3 phase asynchronous induction motor’s compatibility with such controls supports improved operational flexibility and efficiency.

Thermal management is crucial for the reliable performance of Air Compressor Motors. Excessive heat buildup can deteriorate insulation and shorten the lifespan of the 3 phase asynchronous induction motor. Effective cooling methods, including fans and heat exchangers, help maintain safe operating temperatures and preserve motor integrity.

In industrial settings, vibration and mechanical stress are common challenges. Ensuring proper alignment and balance of the motor shaft can reduce vibrations that might otherwise damage bearings or other internal components of the 3 phase asynchronous induction motor. This precaution prolongs the service life of the Air Compressor Motor and supports consistent performance.

Finally, selecting a motor that complies with industry standards and certifications guarantees a level of quality and safety. Compliance with certifications such as CCC, CE, and ISO9001 is often expected for Air Compressor Motors and reflects manufacturing rigor that supports dependable operation of the 3 phase asynchronous induction motor.

Choosing the right Air Compressor Motor and maintaining it properly can cause improved productivity, reduced energy costs, and longer equipment life. Understanding these factors allows operators and engineers to make informed decisions to support their operational goals.